Stainless Steel Grab Bars: The Complete Guide for Commercial Spaces

Safety, accessibility, and durability are the hallmarks of stainless steel grab bars, making them indispensable for commercial environments like restrooms, showers, and healthcare facilities. At Berl’s, we offer only the best, ADA-compliant accessories. These grab bars combine robust construction with customization options, ensuring long-lasting performance and aesthetic appeal. Here’s what you need to know about mounting methods, finishes, sizes, shapes, and the importance of proper installation.

Mounting Options: Concealed vs. Exposed

Effective installation ensures that grab bars serve their purpose while complementing the overall design of a space. Here are the two main mounting options:

•Concealed Mounting with Snap Flange: This approach uses snap-on covers to hide screws, creating a clean and professional appearance. It’s ideal for businesses seeking functionality combined with a polished aesthetic.

•Exposed Mounting: In this option, screws are visible, making installation simple and adding a rugged, durable look. It’s perfect for spaces prioritizing strength and reliability (and of course cost) over design.

Standard Sizes for Straight Grab Bars

Straight grab bars are available in standard lengths, providing flexibility for various installations:

•12 inches

•18 inches

•24 inches

•36 inches

•42 inches

•48 inches

These standardized sizes ensure compatibility with ADA compliance and make it easier to outfit your space with grab bars tailored to your requirements. See our blog about ADA Requirements in Commercial Restrooms.

Shape Options: Functionality for Every Setting

Berl's Commercial Supply offers grab bars in a variety of shapes to accommodate different accessibility needs:

•Straight Grab Bars: The most versatile choice, ideal for walls and flat surfaces.

•Angled Grab Bars: Vertically oriented angled grab bars (sometimes referred to as "Elbow" grab bars.

•Corner Grab Bars: Designed for spaces where walls meet, providing stability in compact areas.

•Wall-to-Floor Grab Bars: Adds vertical support, commonly used near toilets or in showers for enhanced safety.

•Swing-Up Grab Bars: Hinged grab bars that fold up when not in use, saving space while maintaining accessibility.

•Security Grab Bars: Anti-ligature grab bars include closed reinforced designs suitable for high-security environments like correctional facilities or mental health institutions.

Surface Finishes: Smooth vs. Peened

The surface finish impacts both the functionality and appearance of grab bars. Berl’s offers:

•Smooth Finish: Known for its sleek, modern look and easy maintenance, smooth finishes are ideal for commercial restrooms and healthcare settings. This category includes:

•Polished Finish: A highly reflective, mirror-like surface for spaces that demand elegance.

•Satin/Brushed Finish: Offers a subtle matte sheen, combining a refined appearance with practicality. This is the most popular option.

•Peened Finish: Textured for enhanced grip, making it the safer choice in wet environments like showers or poolside facilities.

Berl’s offers grab bars from the top manufacturers, so you can rest assured that you will be getting the best quality that is durable enough for a commercial bathroom setting and also meets ADA requirements.

Backing: A Crucial Step in Installation

A grab bar is only as strong as the wall it is attached to, and the anchors used in installation. To ensure that the bar can support the weight for which it is rated, be sure to add backing to the walls where grab bars are installed. This is normally a block of wood installed behind the wall to give the screws something to bite into. When ordering partitions for your restroom, make sure that backing is included in the design for the grab bars and other accessories. Some materials do not require backing, and other anchors can be used in a pinch, but be sure to discuss this with the manufacturer or your contractor, to make sure you can support a full weight-load.

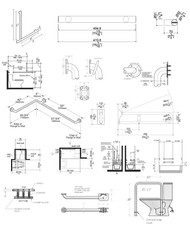

Where to Put Grab Bars in the Shower or Bathtub

When it comes to safety and accessibility in the bathroom, proper placement of grab bars in shower areas is critical. The Americans with Disabilities Act (ADA) provides clear guidance on where and how these bars should be installed to ensure maximum support and usability. Here’s how to get it right based on the type of shower or bathtub:

Roll-In Shower Compartments

In standard roll-in showers without a seat, grab bars must be installed on three walls. This ensures users can support themselves from any position within the shower.

Source: U.S Access Board

For roll-in showers with a folding seat, the placement requirements change:

•Grab bars must not overlap the seat.

•Instead, they must be installed on the back wall (extending to at least the front edge of the seat) and the wall opposite the seat.

Whether the bars are continuous or separated, they must meet the following criteria:

•If separated, each bar must be within 6 inches of the adjacent wall, and all bars must be installed at the same height above the finished floor.

•Bars should be positioned near the shower entry for ease of access.

•Additionally, grab bars must be at least 1½ inches below the shower controls to avoid interference.

Transfer Shower Compartments

In transfer-type showers, which typically have a fixed seat:

•Grab bars must be usable from the seat.

•They are required on the back wall and the wall opposite the seat.

•Similar to roll-in showers, bars can be continuous or separate, but if separate, they must be mounted at the same height above the floor.

•The bars must extend across the control wall and reach to the entry, ensuring users have support from multiple angles.

Bathtubs

For bathtubs, grab bars are required on three walls surrounding the tub. Placement must include:

•One bar on the control end wall and another on the head end wall, both extending all the way to the front edge of the bathtub.

•Although the ADA does not specify a maximum distance from the tub edge, the bars should be as close as possible while still allowing for secure attachment.

Source: U.S Access Board

Additional Considerations

•Height and Clearance: All grab bars should be installed at a uniform height (consistent across all bars in a shower). They should have at least 1½ inches of clearance from the wall and be free from any obstructions. Any projecting objects must be at least 12 inches above the top of the bar, and 1½ inches away from the ends and bottom.

•Vertical Grab Bars: While the ADA does not require vertical grab bars, they can enhance safety, especially when entering a shower or tub. The ICC A117.1 standard, often referenced by local building codes, mandates an 18-inch vertical bar at transfer showers and tubs.

•Durability and Design: Grab bars must be securely anchored to support at least 250 pounds of force. Opt for round or oval shapes with diameters between 1.25" and 2" for optimal grip and comfort.

Source: U.S Access Board

Proper grab bar placement isn’t just about compliance—it’s about ensuring safety, dignity, and independence for everyone using the space.

Types of Stainless Steel: Grades and Rust Resistance

The grade of stainless steel plays a significant role in grab bars' durability and resistance to rust. Here’s what you need to know about the common grades:

•304 Stainless Steel:

The standard grade, 304 stainless steel combines 18-20% chromium and 8-10% nickel for excellent rust resistance and durability. It’s ideal for humid environments like restrooms and showers.

Grab bars made with 18-gauge 304 stainless steel are the most commonly used in commercial settings.

•303 Stainless Steel:

Includes sulfur for enhanced machinability, making it ideal for stylized designs. 303 is not quite as rust-resistant as 304, but in the case of grab bars, it is normally paired with a layer of protective coating. The result is even better rust resistance. The high-end Bobrick Fino Collection, for example, uses 303 stainless, but only with a very durable coating that adds another layer of protection, additional grip, and an aesthetically-pleasing style.

•316 Stainless Steel:

Contains molybdenum for superior corrosion resistance, particularly in extreme environments like coastal areas or poolside installations. We don’t see this option in restroom settings so much, but it is commonly used on saltwater boats since 316 stainless steel is the most rust-resistant option available.

Understanding the Numbers:

•303: Enhanced machinability but less corrosion-resistant than other grades, and paired with additional coatings.

•304: Excellent rust resistance and affordability; the go-to choice for most commercial applications.

•316: Exceptional rust resistance due to molybdenum, ideal for challenging conditions.

Why Stainless Steel is Essential

Stainless steel’s composition makes it highly resistant to rust, even in humid environments. Its unique characteristics include:

•Chromium: Forms a protective oxide layer to shield against rust.

•Nickel: Adds durability and a polished finish.

•Molybdenum: Found in 316-grade stainless steel, enhancing corrosion resistance in harsh conditions.

By choosing the right grade and finish, you’re ensuring your grab bars will perform well for years while requiring minimal maintenance.

Stainless steel that you would not want to use for a commercial grab bar

Inferior stainless steel grades or improperly treated stainless steel can lead to rusting, especially in humid environments like bathrooms or showers. Here are some examples:

201 Stainless Steel:

This is a lower-cost alternative to 304 stainless steel, with reduced nickel content and increased manganese. While it offers some corrosion resistance, it is more prone to rust in high-humidity or chloride-rich environments.

Commonly used in less demanding applications, it lacks the durability needed for grab bars in commercial bathrooms.

430 Stainless Steel:

A ferritic stainless steel with lower nickel content, 430 is less corrosion-resistant than 304 or 316. It performs adequately in mild environments but is not suitable for areas with constant exposure to moisture or chlorides.

Often used in decorative applications or kitchen appliances, it is not ideal for safety-critical installations like grab bars and would show rust spots in a restroom.

Improperly Treated Stainless Steel:

Even high-quality grades like 304 or 316 can rust if not properly treated or maintained. For example:

Surface Contamination: If stainless steel is contaminated with iron particles during manufacturing or installation, these particles can rust and compromise the protective chromium oxide layer.

Improper Cleaning: Using abrasive cleaners or tools can damage the surface, exposing the underlying metal to moisture and oxygen.

Low-Chromium Alloys:

Stainless steel with chromium content below 10.5% does not form a sufficient protective oxide layer, making it highly susceptible to rust. Such alloys are not typically classified as stainless steel and should be avoided for grab bars.

To make sure you are getting only the best, all of the manufacturers that work with Berl’s Commercial Supply use high-quality grades of stainless steel, such as 304, for grab bars. Proper maintenance, such as regular cleaning with non-abrasive products intended for care of stainless steel, also helps to preserve the protective layer and prevent rust.

Color Options

While stainless steel is the default choice for grab bars, Berl’s also offers additional options, including white and black for spaces that require enhanced visibility or specific design aesthetics. And vinyl-coated grab bars in other colors are also available via special order.

Where to Buy

Berl’s Commercial Supply provides a wide selection of stainless steel grab bars, from standard straight bars to angled, swing-up, and security designs. With top-quality manufacturing and ADA compliance, Berl’s is your trusted source for reliable grab bars. Shop now at www.berls.com.

Investing in stainless steel grab bars means ensuring accessibility, safety, and style for your commercial spaces. With the right grade, surface finish, and installation (remember to include backing and the correct weight-rated fasteners), you can meet ADA standards and create a reliable environment that stands the test of time. Let Berl’s Commercial Supply help you make the best choice for your facility today!